see dtl’s ExquisiteFonts website!

| Home | Search | Site index | About | Contact |

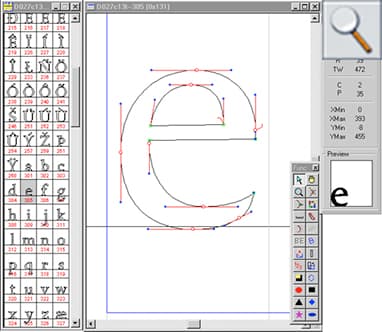

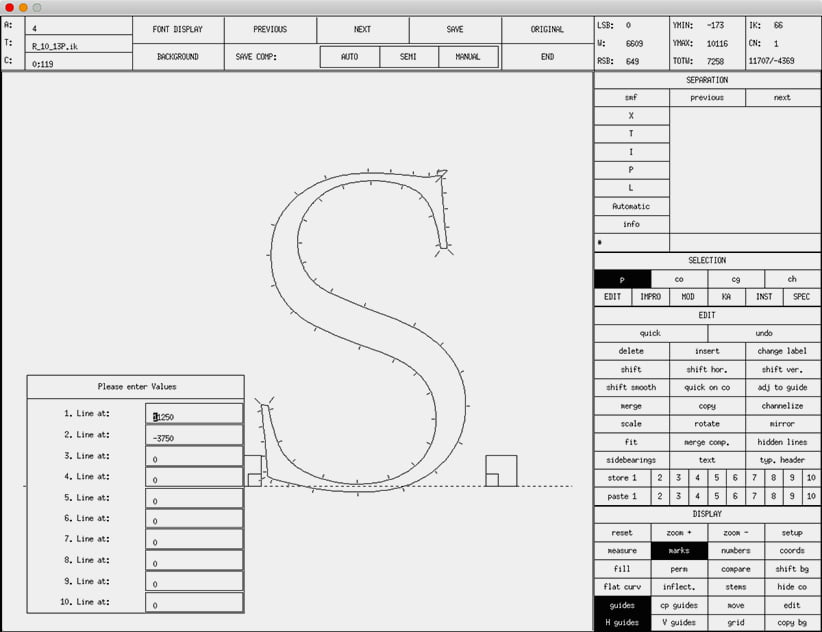

Digitizing in the ikarus format (left) and a contour in Bezier format in dtl BezierMaster

Font production is a term that encompasses many different activities that should ultimately result in digital typefaces.

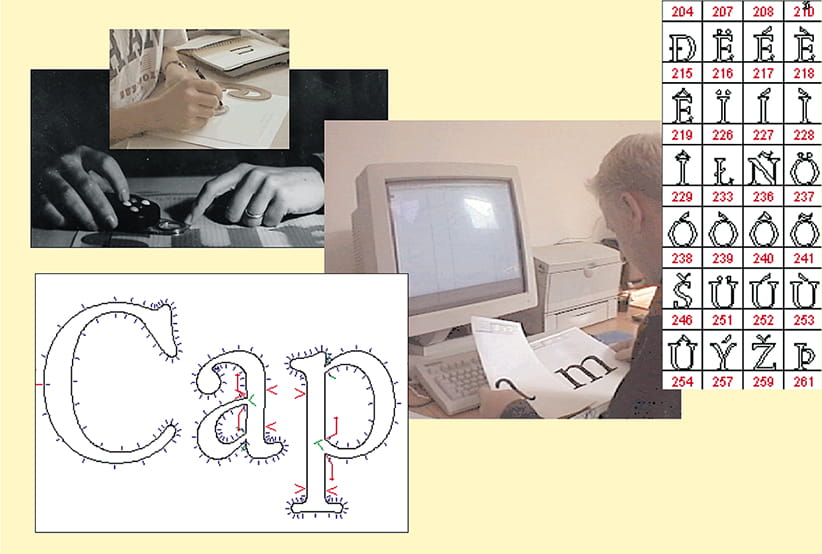

First, a typeface has to be designed; this can be on paper or directly digitally on the computer screen, or even a combination of these approaches. At the Dutch Type Library it is still preferable to make the first series (or sometimes all) drawings on paper and to use a lens cursor and tablet for digitization in combination with dtl IkarusMaster, part of the dtl FontMaster suite. The auto-trace program dtl TraceMaster or the auto-tracer in dtl FoundryMaster are also used to convert analog material to digital data. Based on the quality of the drawings, it is determined which method is best for conversion to digital contours.![]()

![]()

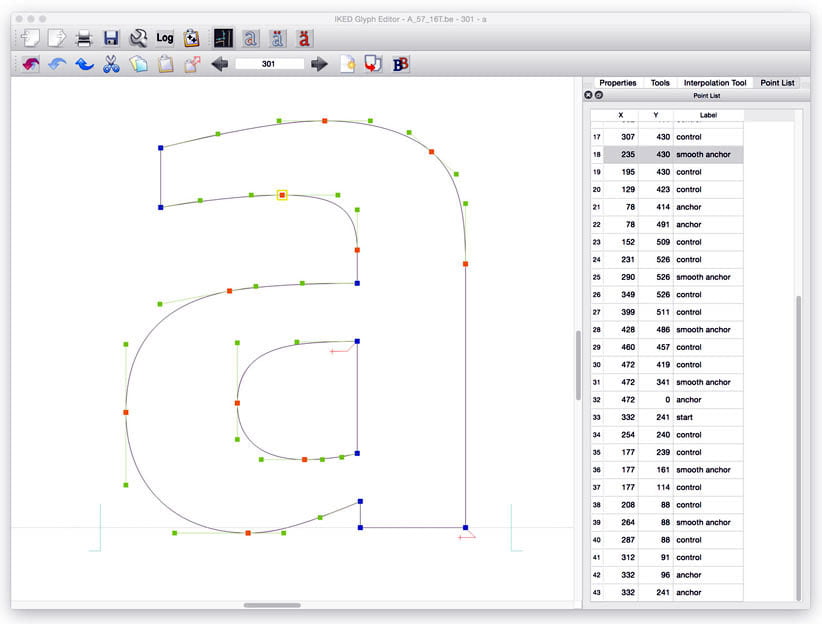

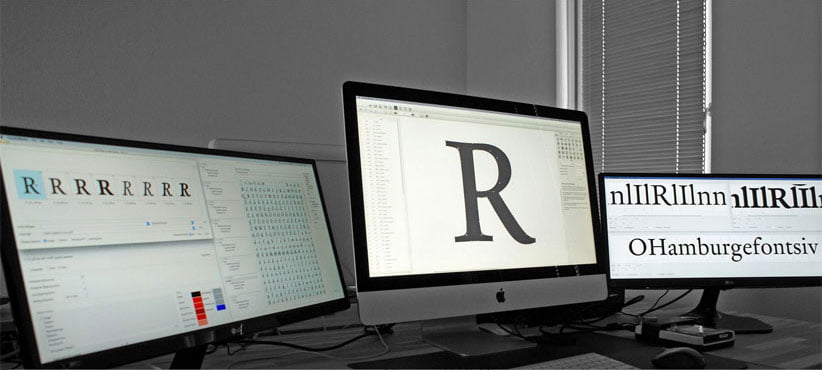

Fonts are designed and produced with dtl FoundryMaster![]()

Second is the construction of the glyph databases. This is done in an editor, in our case dtl FoundryMaster for editing Bézier and ikarus contours. Part of the database development is, of course, interpolation to generate different weights.

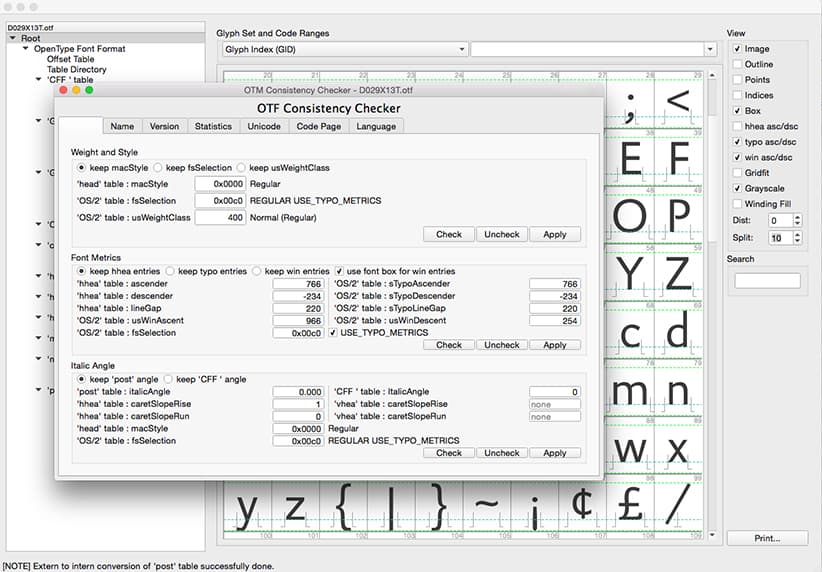

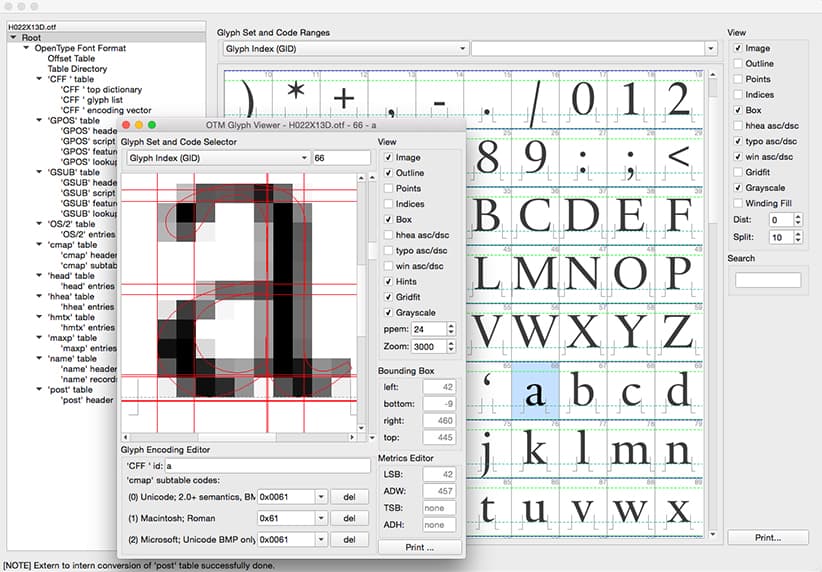

Third is the actual production and post production of fonts, which involves checking the glyph data and generating the fonts in a variety of formats. This is done with dtl FontMaster, dtl FoundryMaster, dtl CompareMaster, and dtl OTMaster.![]()

![]()

The fonts’ consistency is checked with dtl OTMaster![]()

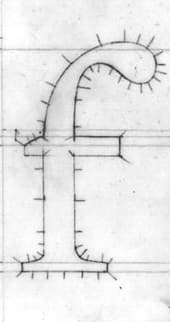

The design itself should determine the most preferred production. For almost all dtl typefaces, production starts with drawings that are manually digitized. Revivals such as dtl Fleischmann, dtl Fell, and dtl VandenKeere were made entirely on paper and then manually digitized to preserve as much detail as possible. The basic character sets of dtl Romulus were also digitized in ikarus.![]()

![]()

ikarus digitization of dtl Romulus![]()

The ikarus workflow at dtl is quite simple. First, glyph drawings are created at a relatively small size and are (usually) spaced. Perfect working drawings are then made at a capital height of 10 cm on high-quality transparent paper or polyester film, depending on the preferences of the draftsman. These drawings are marked (on the back of the transparent sheets) on the contours with curve, corner, and tangent points according to the ikarus algorithm. One of these points becomes the start point (there is an order for that). A lens cursor is precisely placed on each point and the relevant button for the point type is pressed. This requires some experience, but is a relatively quick and simple process. After all, the main work was done when the working drawings were made.![]()

![]()

ikarus workflow at Dutch Type Library![]()

There is a good reason to keep the different parts of font production separate, especially if there are more people working on a typeface. For example, the designers do not need to be involved or bothered by testing the consistency of the data and actually generating the fonts. This production process is actually also recommended for the educational world: do not confuse students with all the technical stuff before they have even started creating designs.![]()

![]()

The dtl font tools offer a lot of sophisticated functionality![]()

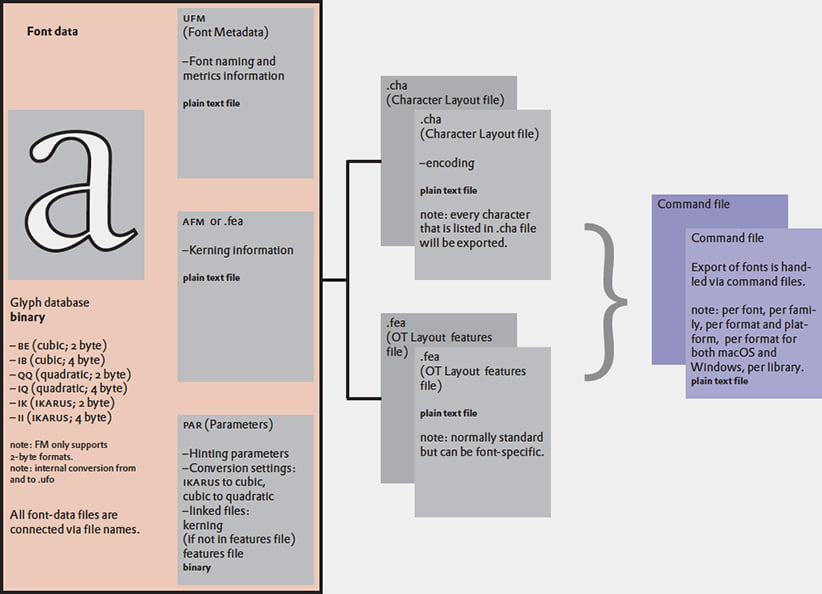

Font production is complex, especially when processing large databases to produce extended Unicode fonts. In dtl FontMaster, a be (this is the native format that fm uses to store the Bézier format) or ik (ikarus) database can contain up to 65,000 glyphs (dtl FoundryMaster supports the 4-Byte ib, ii, and iq formats). There is no information about Unicode numbers or PostScript names in the database. The glyphs only have a number in the database that corresponds to a Character Layout file (.cha). This file contains the naming and Unicode information and the character’s position in one or more code pages.![]()

![]()

dtl’s font-production workflow![]()

This file system is actually not new: the power users of ikarus will be familiar with it. The basic idea behind this file system is that everyone can define their own database with associated Character Layout file and that, for example, a character-name change for an entire font library can be achieved by changing the Character Layout file just once. Or in the case where a character, such as the Euro, needs to be added to a series of databases, all that is required is to insert the glyph at a specific location in the database and add the associated naming and Unicode information to the Character Layout only once. out to be added file. Batch functions in our proprietary editors help expand the databases with, for example, Eastern/Central Europea, Turkish, Cyrillic, Greek, etc. character sets.![]()

![]()

dtl OTMaster is used for checking the hinting (rounding for low-resolution devices)![]()

The font producer wants the most robust conversion of the glyph data to current font formats. Normally the end user is only interested in the quality of the design and wants to make sure that the fonts function properly technically. Over time, the only thing that endures is the design itself. Apart from a few technicians and historians, almost no one in the future will be interested in the current technology used to create the type. If the design is good, it will survive and otherwise it will be forgotten, no matter how interesting we find the way the technology was used now. And then for the font producer there is the long-term technology, the digital contour description, and the short-term technology that preserves the best conversion to limited equipment, such as delta hints. In the (relatively) long term, only the contours will be the constant factor and the short-term technology will inevitably constantly change.

For the production of the very exquisite dtl fonts, the Dutch Type Library uses the internally developed dtl FontMaster suite

Search | Site index | Contact | Terms of use | Trademarks | Acknowledgements

Last update: 18 November 2024. Copyright © Dutch Type Library, 1998–2024. All rights reserved

dtl Headquarters | Zwaenenstede 49 | 5221 kc ’s-Hertogenbosch | The Netherlands

dtl Studio | Daliënwaerd 71 | 5221 ke ’s-Hertogenbosch | The Netherlands

phone: +31 (0)73 614 95 36 | fax: +31 (0)73 613 98 23 | e-mail: info@dutchtypelibrary.com